FR4

FR4 is a class of printed circuit board base material made from a flame retardant epoxy resin and glass fabric composite. FR stands for flame retardant and meets the requirements of UL94V-0. FR4 has good adhesion to copper foil and has minimal water absorption, making it very suitable for standard applications. FR4 is either used as a copper-coated material for 1 and 2-layer PCBs or is used for multilayer PCBs as a Prepreg and core.

The glass transition (Tg) for Flame Retardant 4 lies between 115°C and 200°C, depending on the manufacturing method and resin material. The material gains its fire-resistant properties from the presence of the halogen chemical element bromine. FR4 also features a high strength-to-weight ratio and high hardness, ensuring the material will not break easily under load or during machining.

While Flame Retardant 4 is well-known for fabricating PCBs, it also provides an ideal material for:

- Industrial Wear Applications

- Electrical Insulation

- Screw Terminal Strips

- Transformers

- Arc Shields

- Washers

- Busbars

- Standoffs

- Switches

- Relays

Size: 1020mm * 1220mm, 1020mm * 2040mm, 1220mm * 2440mm

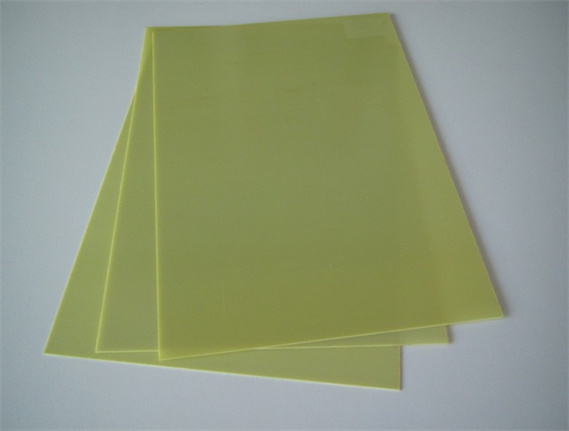

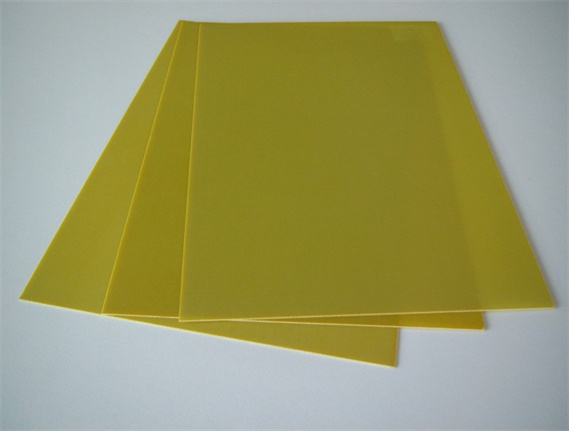

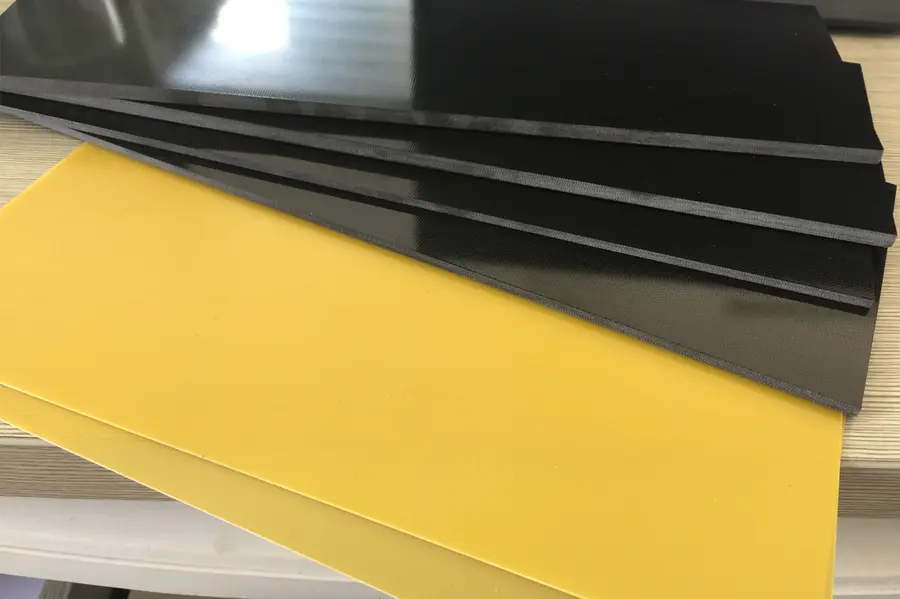

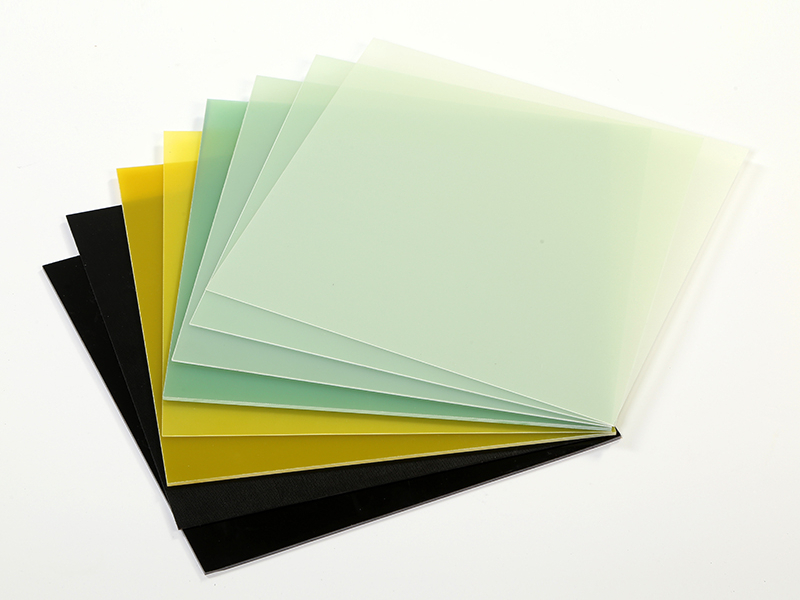

Color: Yellow, Natural, Green, Black, White, etc.

Length, width, thickness, and diameter tolerances vary by size, by manufacturer, brand, and grade. Custom sizes and colors available upon request.

FR-4 Glass Epoxy Laminate, often simply referred to as FR4, has become a popular material in various industries due to its excellent strength, durability, and flame resistance.

FR4, G10, and G11 are all common materials used in the electronics and industrial fields, particularly in the manufacture of printed circuit boards (PCBs) and insulation applications.

The density of FR4 material is approximately 1.85 g/cm³. This is an average value, and the exact density can vary slightly depending on the specifics of the FR4 formulation used.