The Production Process of FR-4 Glass Epoxy Laminate

FR-4 Glass Epoxy Laminate, often simply referred to as FR4, has become a popular material in various industries due to its excellent strength, durability, and flame resistance. As a crucial component of modern printed circuit boards (PCBs), understanding the origin, material characteristics, and production process of FR4 is vital for anyone engaged in the industry.

1. The Naming Origin of FR4:

The term “FR4” stands for “Flame Retardant 4”. The number 4, in this context, represents the epoxy used in the laminate – a standard “4” or E-class glass epoxy. The “FR” denotes the material’s flame-retardant property, reflecting its ability to resist burning in the event of a fire. It’s a necessary feature for electrical insulation materials, reducing risks and ensuring safety in the application of electronic devices.

2. Material Characteristics of FR4 Sheet:

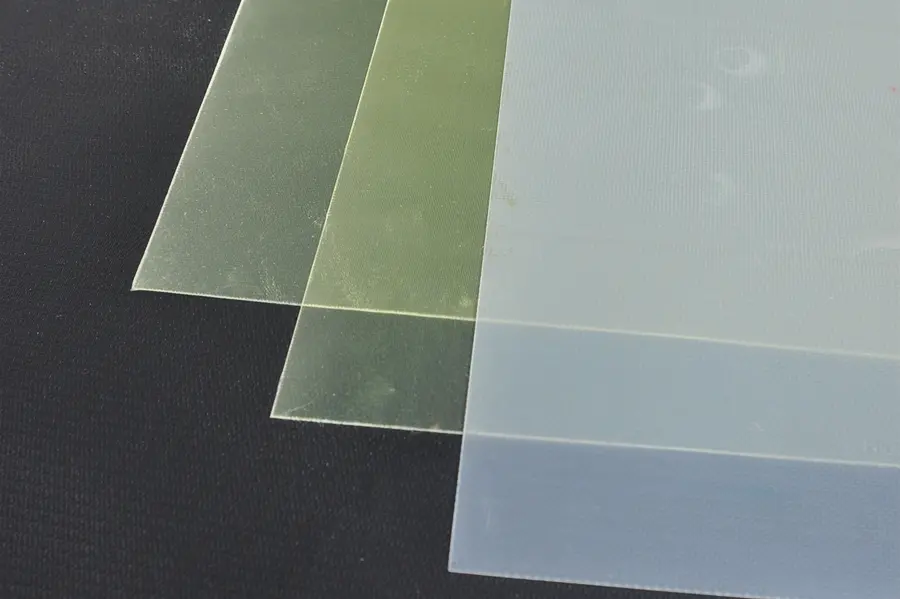

FR4 sheets are composed of woven fiberglass cloth, impregnated with an epoxy resin binder. The original material characteristics inherited by the FR4 sheets are primarily derived from these two components.

The fiberglass cloth provides high strength, dimensional stability, and excellent electrical insulation properties. It ensures the mechanical robustness of the FR4 laminate, offering excellent structural support for the electronic components mounted on the board.

The epoxy resin binder, on the other hand, contributes to the FR4’s thermal resistance, chemical resistance, and high adhesive strength. It binds the fiberglass layers together and creates a sturdy matrix that can endure various environmental conditions, including heat, moisture, and chemicals.

3. The Production Process of FR4 Board:

The manufacturing process of an FR4 board involves several key steps. First, the fiberglass cloth is thoroughly soaked in epoxy resin, ensuring that each thread is entirely impregnated with the resin.

Once impregnated, the soaked fiberglass is placed into a heat press. Under controlled temperature and pressure, the heat press initiates the curing process of the epoxy resin. It transforms the liquid resin into a solid, rigid structure, binding the fiberglass cloth layers together. This process creates what is known as a ‘prepreg’ – an intermediate product in the FR4 production process.

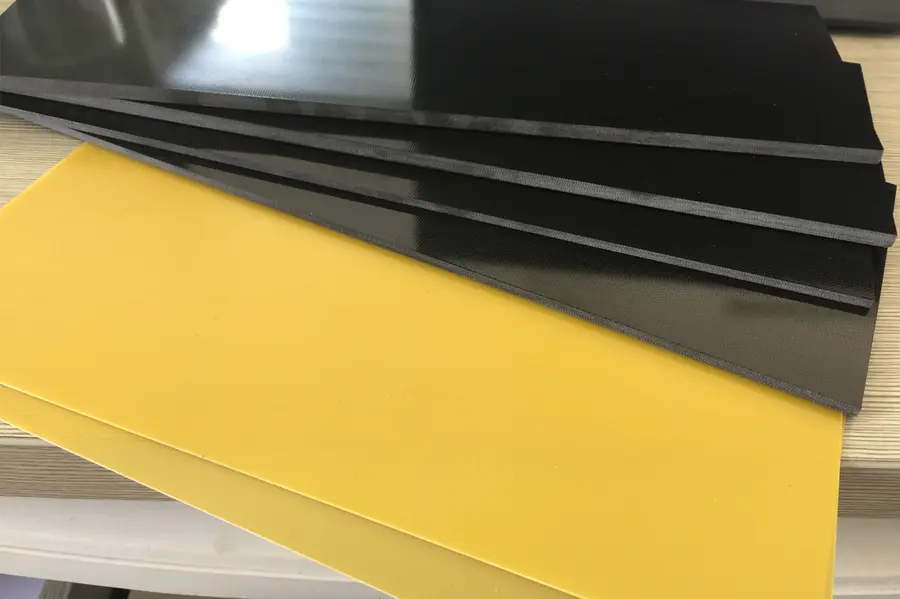

Several layers of prepregs are then stacked together, along with copper foils that will form the circuit pattern. The stack is again placed into a press, where it is subjected to high heat and pressure. This process bonds the layers into a single, unified structure, turning the copper into circuit pathways.

The resulting laminate, the FR4 board, is then cooled and subjected to quality checks. The finished product is a strong, durable, and flame-resistant board, ready to be used in the manufacture of PCBs.

The FR4 Glass Epoxy Laminate, as a combination of woven fiberglass cloth and epoxy resin, showcases the advantages of both materials and plays a crucial role in the electronics industry. The precise and controlled production process ensures the strength, flame resistance, and electrical insulation properties that define FR4, rendering it indispensable in the modern world.