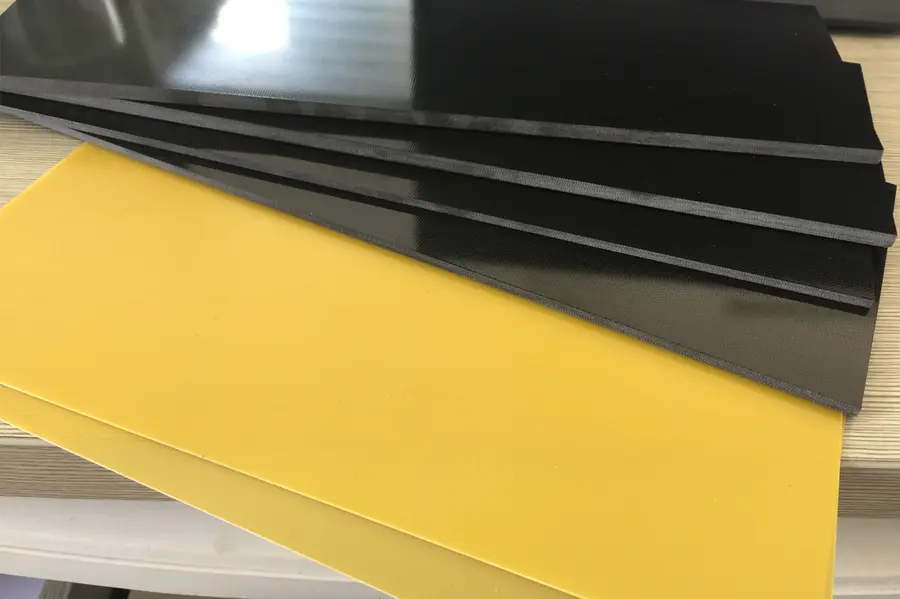

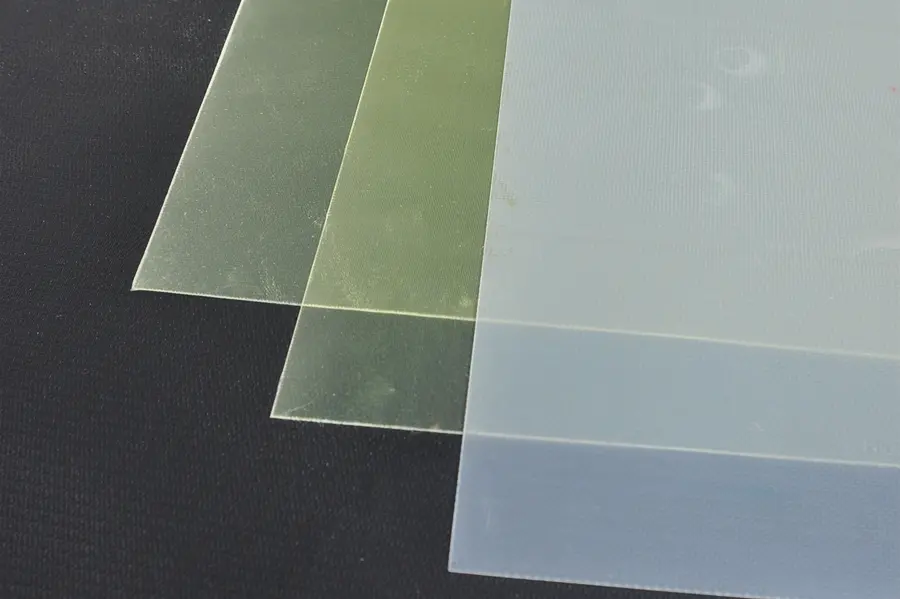

Guidelines for Proper Storage of Fiberglass Prepregs

Prepregs, often the base material for FR4 insulation boards, are a type of composite material formed by impregnating a reinforcement fabric, like fiberglass, with a resin system. The resin system typically includes a curing agent, which allows the prepreg to harden under heat and pressure. Managing the storage of these materials is crucial to maintain their quality and performance.

1. Temperature Control:

Maintaining an appropriate storage temperature is critical for fiberglass prepregs. Since prepregs contain a partially cured resin, they need to be stored at low temperatures to prevent premature curing. Typically, the storage temperature should be around -18°C (0°F). At this temperature, the resin remains in a semi-cured state, thereby preserving its usability.

2. Shelf Life Considerations:

Even with low-temperature storage, prepregs have a limited shelf life. Over time, the resin system can continue to cure, albeit slowly. Therefore, prepregs should be used within the specified shelf-life period provided by the manufacturer to ensure optimal performance.

3. Packaging and Handling:

Fiberglass prepregs should be kept in their original packaging until they are ready to be used. This packaging is designed to protect the prepreg from moisture, which can affect the curing process. When handling prepregs, care should be taken to avoid damage to the resin-impregnated fibers, as this could impact the material’s performance.

4. Thawing:

Before use, prepregs need to be thawed from their storage temperature to room temperature. This should be done gradually to prevent condensation, which could interfere with the curing process. Once thawed, prepregs should be used as soon as possible to prevent premature curing.

Proper storage and handling of fiberglass prepregs are essential to ensure their quality and performance. By maintaining appropriate storage temperatures, respecting the shelf life, and handling the materials correctly, you can get the most out of your prepregs when producing FR4 insulation boards.