Understanding the Role of Fiberglass Prepregs in Composite Material Production

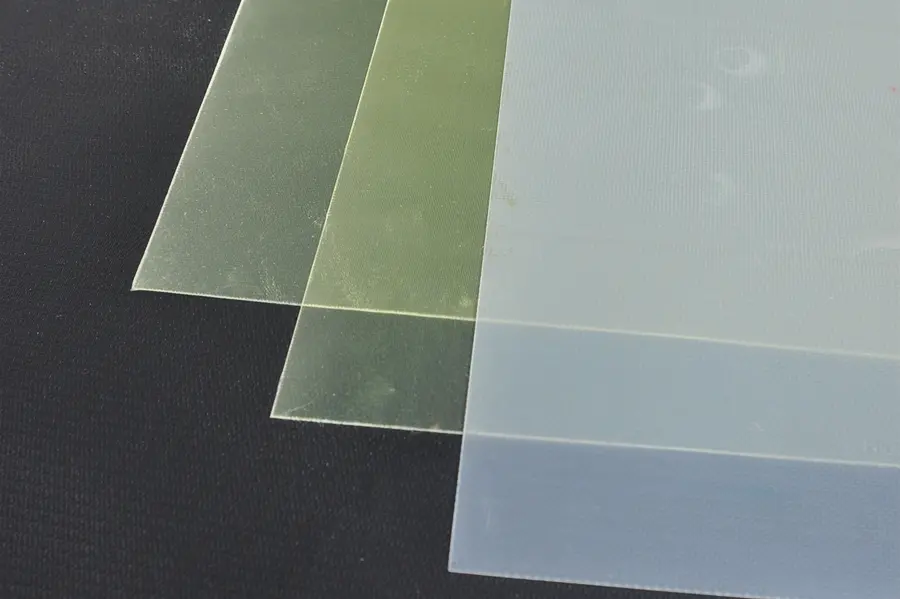

Many composite materials are indeed made from fiberglass prepregs. Prepreg is short for “pre-impregnated,” and refers to the process where the fibrous reinforcement, in this case, fiberglass, is pre-impregnated with a resin system.

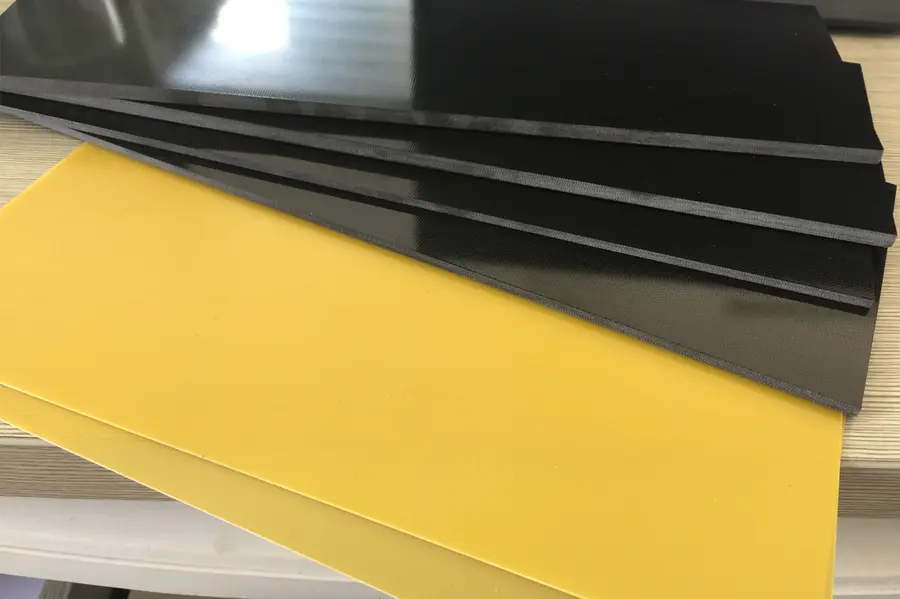

The process of making composite materials using fiberglass prepregs involves applying heat and pressure to the pre-impregnated fibers. The heat activates the resin system, causing it to flow, fill the spaces around the fibers, and then cure, hardening to form a rigid material. The resulting composite material combines the strength and durability of the fiberglass with the hardness and resistance to chemicals and temperature of the resin, providing a high-strength, lightweight material.

These composites are used in a wide range of applications, including aerospace, automotive, marine, and sporting goods, among others. In each of these applications, the composite’s high strength-to-weight ratio, corrosion resistance, and ability to be molded into complex shapes are highly valuable. Notably, FR4 boards, commonly used for printed circuit boards (PCBs) in the electronics industry, are made from fiberglass prepregs.

That said, it’s important to note that not all composite materials use fiberglass prepregs. Other types of fibrous reinforcement, like carbon or aramid fibers, can also be used, each providing different properties to the resulting composite. Similarly, different types of resin systems can be used in the prepreg, again affecting the properties of the final material.