Differentiating FR4, G10, and G11 Sheets: A Comparative Overview

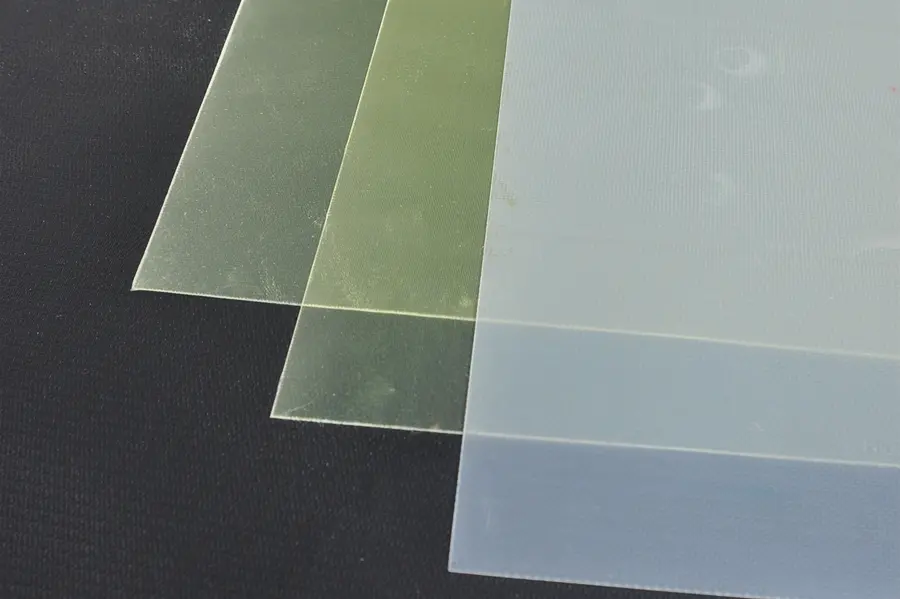

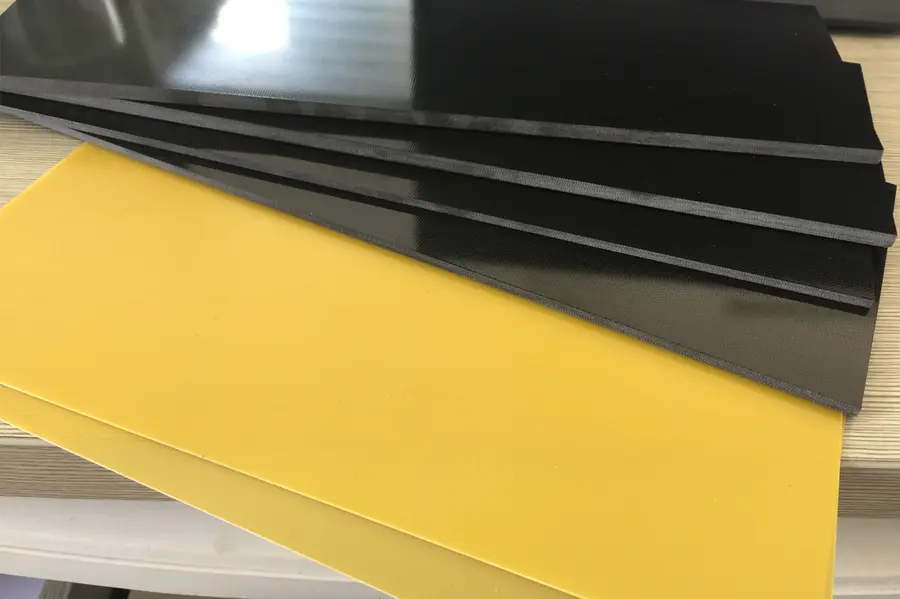

FR4, G10, and G11 are all common materials used in the electronics and industrial fields, particularly in the manufacture of printed circuit boards (PCBs) and insulation applications. Although they share certain characteristics, such as being composed of woven fiberglass and epoxy resin, there are significant differences that determine their use in specific applications. Understanding these differences is critical for material selection and optimal performance.

1. FR4 Sheets:

FR4, or Flame Retardant 4, is the most widely used laminate for PCBs. It’s composed of woven fiberglass cloth impregnated with a flame-resistant epoxy resin. The “FR” indicates its flame-retardant properties, making it safer in the event of a fire. Additionally, FR4 has excellent mechanical strength, dimensional stability, and electrical insulation properties, which are inherited from its fiberglass and epoxy resin components. It can withstand relatively high temperatures, but its performance may degrade slightly at extremely high temperatures.

2. G10 Sheets:

G10 was the precursor to FR4 and is also composed of woven fiberglass cloth and epoxy resin. However, unlike FR4, G10 doesn’t possess flame-retardant additives. As a result, while it maintains comparable mechanical and electrical insulation properties to FR4, it may pose more of a fire risk. G10 is known for its excellent dimensional stability and lower water absorption rate, making it suitable for applications in moisture-rich environments.

3. G11 Sheets:

G11 is an upgraded version of G10. It also consists of woven fiberglass cloth, but the epoxy resin used in G11 is modified to withstand higher temperatures. This makes G11 a class apart, as it retains its electrical insulation properties and mechanical strength even at extremely high temperatures. Like G10, G11 does not contain flame-retardant additives, but its high-temperature resistance surpasses both G10 and FR4. Consequently, G11 is used in applications that require long-term temperature endurance.

While FR4, G10, and G11 are all laminates composed of woven fiberglass cloth and epoxy resin, they vary in terms of flame retardance and heat resistance. FR4 is flame retardant but has moderate heat resistance. G10 is not flame retardant, but its water resistance and dimensional stability make it suitable for certain environments. Finally, G11 is renowned for its superior heat resistance, making it ideal for high-temperature applications.

Understanding these differences is critical when selecting the appropriate material for specific use-cases. Always consider the operational environment, including factors like heat, flame exposure, and moisture, when choosing between FR4, G10, and G11 sheets.