Key Considerations when Procuring 3240 Epoxy Glass Fiber Sheet

The procurement of technical materials like the 3240 Epoxy Glass Fiber Sheet requires a strategic approach to ensure that all necessary performance and quality factors are taken into account. Whether for industrial applications such as in transformers, circuit breakers, or electrical insulation, a meticulous purchasing plan is crucial.

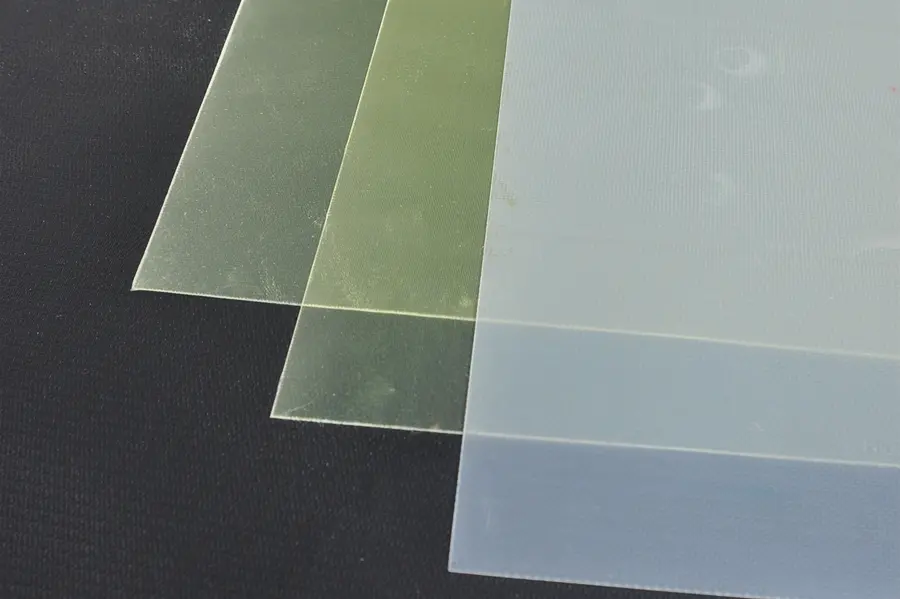

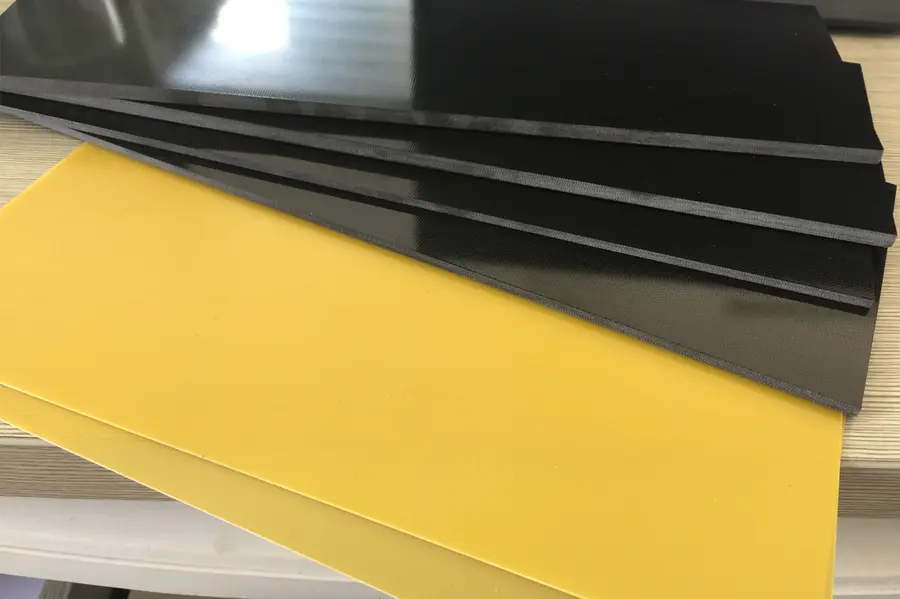

1. Considering the performance characteristics of 3240 epoxy fiberglass board.

This material is known for its high mechanical strength, excellent electrical properties, superior heat resistance, and chemical stability. Therefore, these performance properties should align with your project’s technical specifications and requirements. You must ensure that the sheet you are procuring offers the required mechanical, electrical, and thermal performance, while also being resistant to the chemicals it may be exposed to in the application environment.

2. The quality and reliability of suppliers, and the selection of powerful suppliers

Since the 3240 Epoxy Glass Fiber Sheet is a technical product, it is crucial to purchase from a supplier with a good reputation for quality. The supplier should have a consistent track record of meeting standards, such as IEC (International Electrotechnical Commission) or NEMA (National Electrical Manufacturers Association) for electrical materials. Furthermore, they should have a well-structured quality control process, preferably certified by a recognized authority such as ISO (International Organization for Standardization).

3. Product quality and price, choose the product that suits you

While it is important to prioritize quality and performance, cost-effectiveness should not be overlooked. Evaluate the total cost of ownership, which encompasses the purchase price, delivery costs, potential maintenance costs, and the expected lifespan of the sheets. Sometimes, a slightly higher upfront cost may result in significant long-term savings due to the product’s longevity and minimal maintenance requirements.

4. Pay attention to the supplier’s after-sales service

Technical products like the 3240 Epoxy Glass Fiber Sheet may require specialized handling, storage, and maintenance. As such, it’s essential to ensure that the supplier offers robust after-sales service, including technical support and guidance, warranties, and prompt resolution of any issues that may arise.

5. Consider environmental impacts

The 3240 Epoxy Glass Fiber Sheet should ideally be produced following responsible manufacturing practices that minimize environmental harm. Look for suppliers who have sustainability policies in place and who strive to reduce the environmental impact of their operations.

Procuring 3240 Epoxy Glass Fiber Sheets is not just about buying a product; it’s about making a well-informed decision that considers performance characteristics, supplier reliability, cost, after-sales support, and environmental sustainability. These factors ensure that you not only get a product that meets your project’s needs but also contributes to a more efficient and sustainable operation. This strategic approach to procurement will likely enhance project outcomes, providing you with more value for your investment.