The Application of 3240 Epoxy Board in Transformers

As technological advancement continues to shape industries around the world, the importance of selecting the right materials for manufacturing and design processes cannot be overstated. In the electrical and electronic industry, materials with outstanding properties are essential to ensure optimal functionality, durability, and safety. One such indispensable material is the 3240 Epoxy Board, especially in transformer applications.

The performance of the 3240 Epoxy Board is an essential aspect to consider.

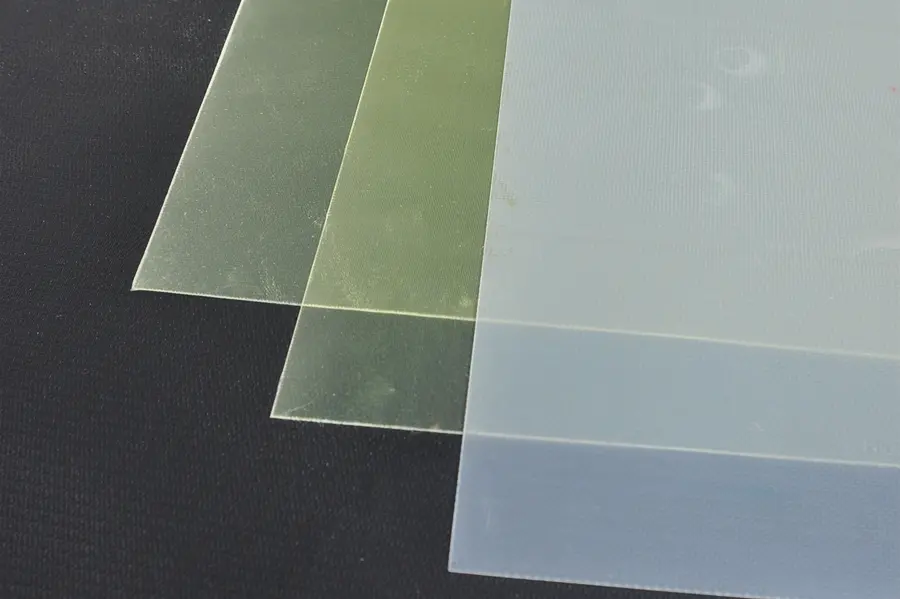

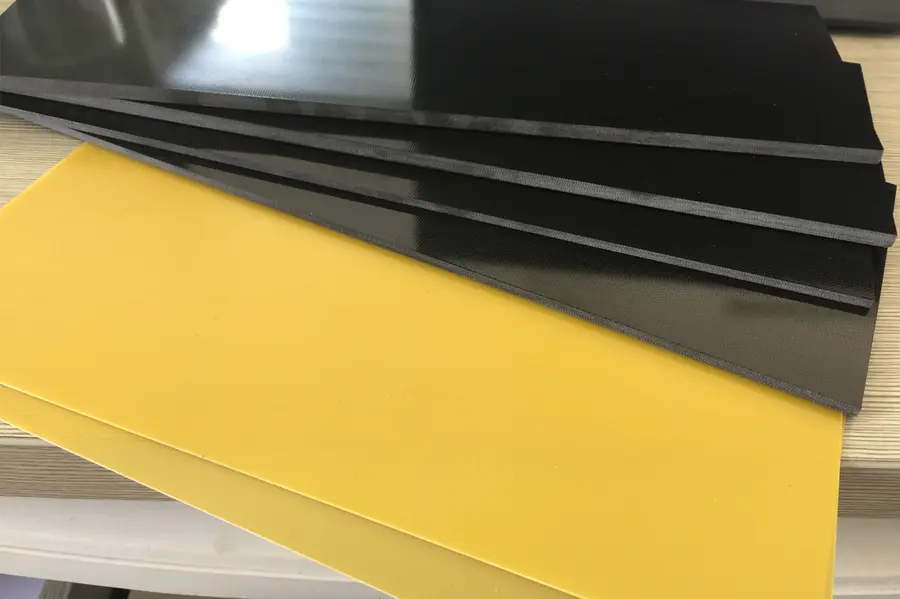

3240 Epoxy Board is composed of woven glass cloth impregnated with epoxy resin under heat and pressure. The resultant product possesses remarkable characteristics, including high mechanical strength, excellent electrical performance under dry and humid conditions, and superb heat resistance. It has a heat resistance class of B, capable of withstanding a temperature of up to 130 degrees Celsius. Moreover, the 3240 Epoxy Board demonstrates considerable chemical resistance and is characterized by its flame retardance, thereby ensuring safety in the face of potential hazards.

It is important to understand the environmental conditions faced by the components in transformers.

Transformers are typically subjected to harsh environments, including exposure to high temperatures, strong electrical fields, and mechanical vibrations or shocks. Additionally, they may be exposed to moisture and various chemicals during their lifespan. These conditions can potentially lead to corrosion, electrical breakdown, and other forms of damage, making the choice of material for the components critical for the transformer’s overall performance and longevity.

Given its performance and the harsh conditions in transformers, it becomes evident why the 3240 Epoxy Board is extensively used in transformer applications. Its high mechanical strength makes it suitable for withstanding the intense physical stresses inside the transformer. Its excellent electrical properties, including dielectric strength and electrical insulation, contribute to reducing the risk of electrical breakdowns, enhancing the transformer’s efficiency and safety. The board’s commendable heat resistance can effectively cope with the high temperatures generated in transformers, thereby reducing the likelihood of overheating and extending the transformer’s operational lifespan. Furthermore, its chemical resistance offers additional protection against potential corrosion caused by environmental exposure.

3240 Epoxy Board’s outstanding properties make it an ideal material for transformer applications. Its high mechanical strength, superb electrical performance, excellent heat resistance, and considerable chemical resistance collectively contribute to its extensive use in transformers. These properties equip it to effectively cope with the harsh environmental conditions faced by transformer components, thereby enhancing the efficiency, durability, and safety of the transformers. The continued application of 3240 Epoxy Board in transformers reflects its integral role in the progression and innovation of the electrical and electronic industry.