Why G10 Epoxy Boards Typically Use 7628 Glass Fiberglass Cloth Prepregs

In the production of G10 epoxy boards, one of the essential materials employed is the 7628 glass fiberglass cloth prepregs. The choice of this specific prepreg type is not random but is influenced by its distinct characteristics that align with the required properties of G10 epoxy boards.

1. Material Composition and Properties:

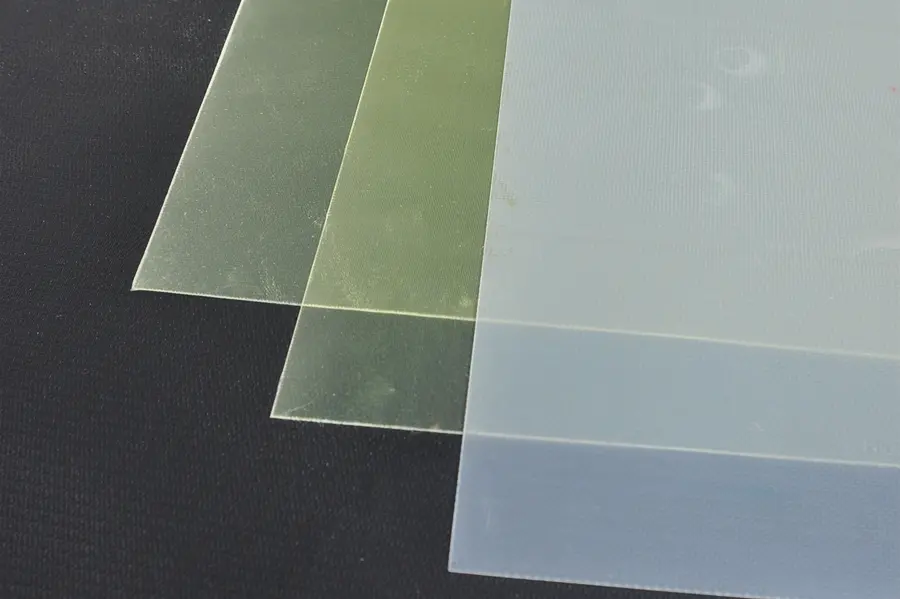

7628 glass fiberglass cloth is a type of electronic-grade fiberglass cloth with a light, tight weave pattern. It provides a smoother surface finish, making it an ideal choice for applications requiring detailed machining or finishing like G10 boards.

2. High Structural Integrity:

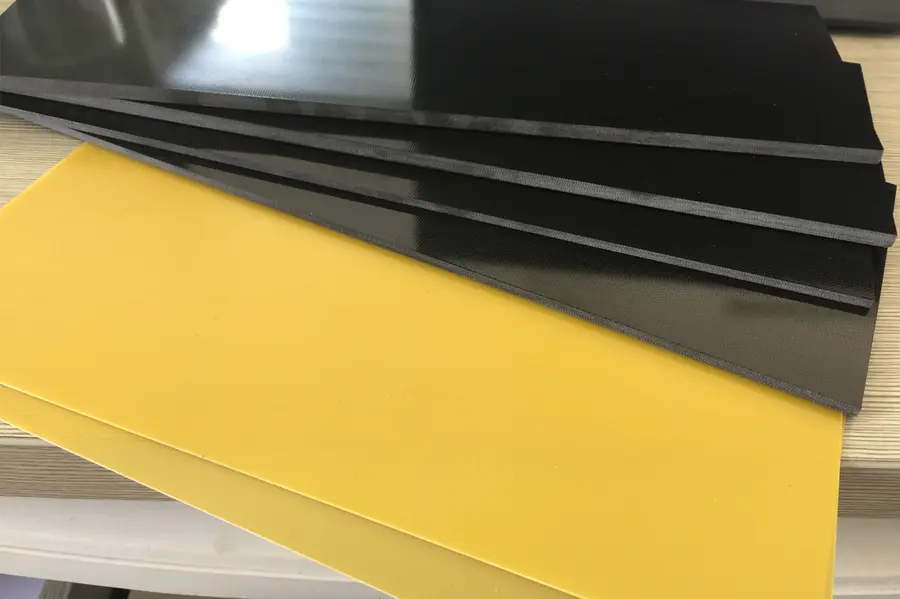

G10 epoxy boards are known for their high mechanical strength and dimensional stability. The use of 7628 glass fiberglass cloth prepregs in their production contributes significantly to these characteristics. The tightly woven fiberglass fabric in these prepregs provides excellent structural support and stability.

3. Enhanced Electrical Insulation:

In addition to mechanical strength, G10 epoxy boards need to provide excellent electrical insulation. The 7628 fiberglass cloth, being electronic-grade, exhibits excellent dielectric properties, making it a suitable prepreg choice for G10 board production.

4. Manufacturing Compatibility:

The 7628 fiberglass cloth’s light and tight weave pattern facilitate the impregnation process with the epoxy resin, creating a uniform and consistent prepreg. This ensures that the resulting G10 epoxy board has uniform mechanical and electrical properties throughout.

The choice to use 7628 glass fiberglass cloth prepregs in the manufacture of G10 epoxy boards stems from their unique properties and compatibility with the required features of the final product. They contribute to the G10 board’s high structural integrity, superior electrical insulation, and smooth finish, all crucial for the board’s performance and longevity.